What Is Concrete Core Drilling?

What is Core Drilling?

How Does the Process of Core Drilling Work?

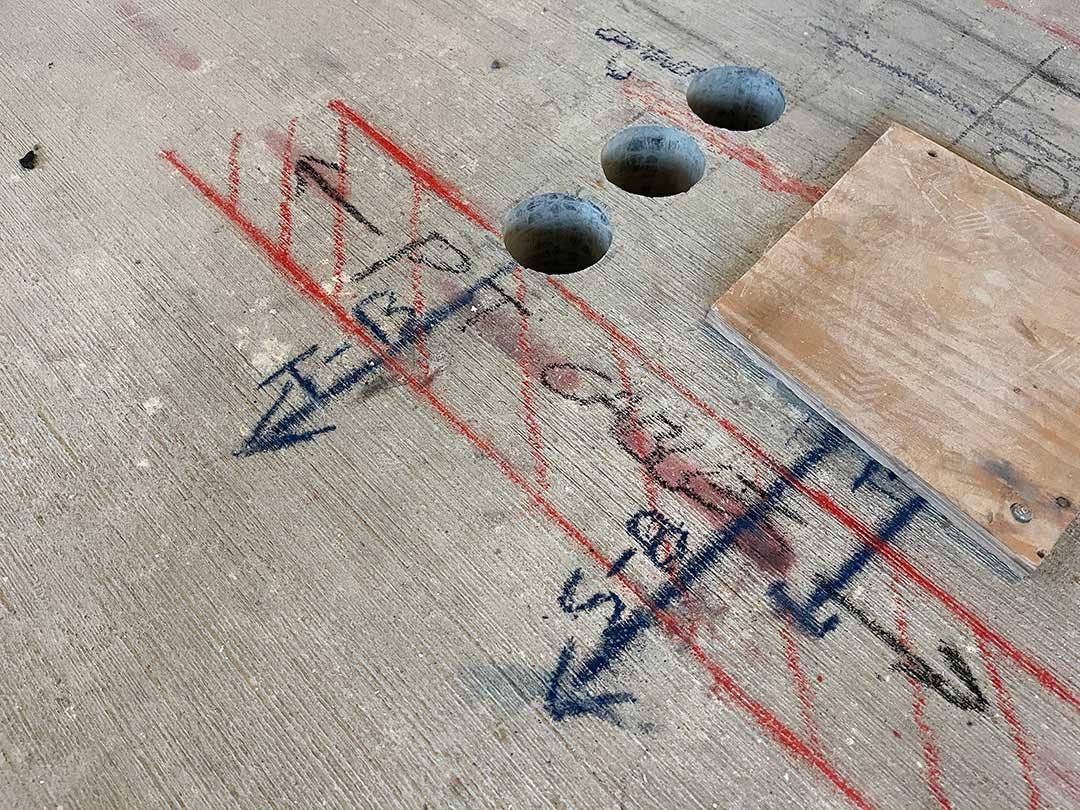

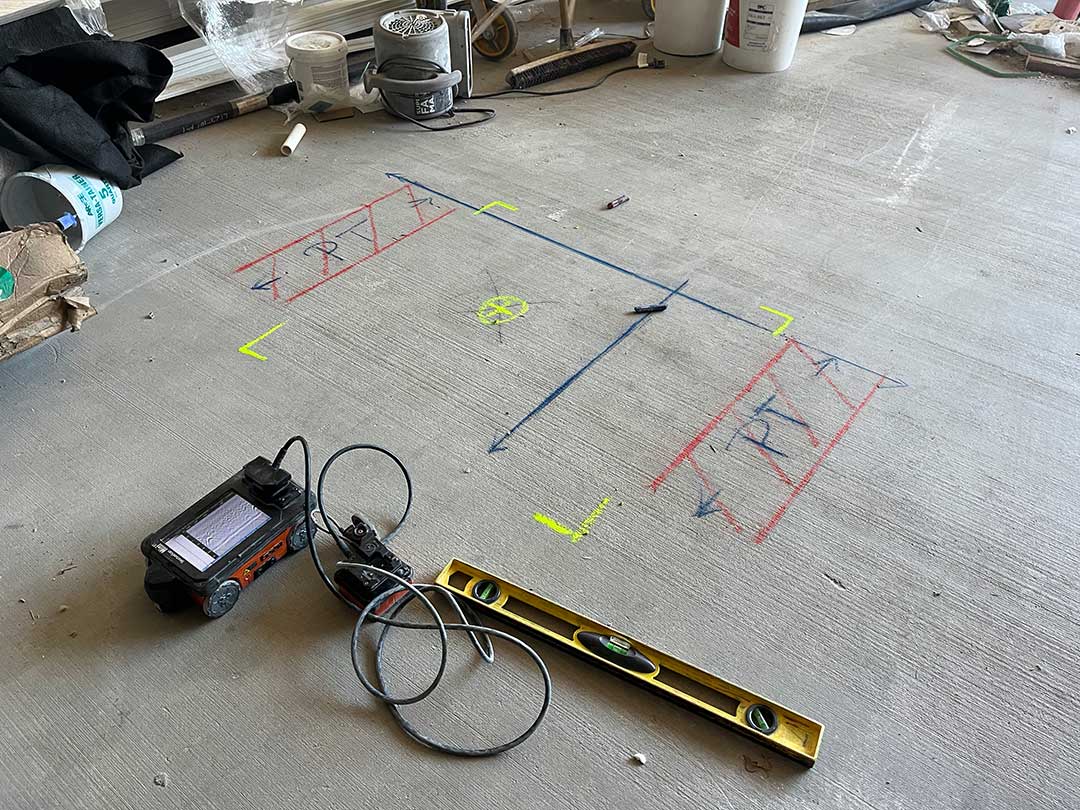

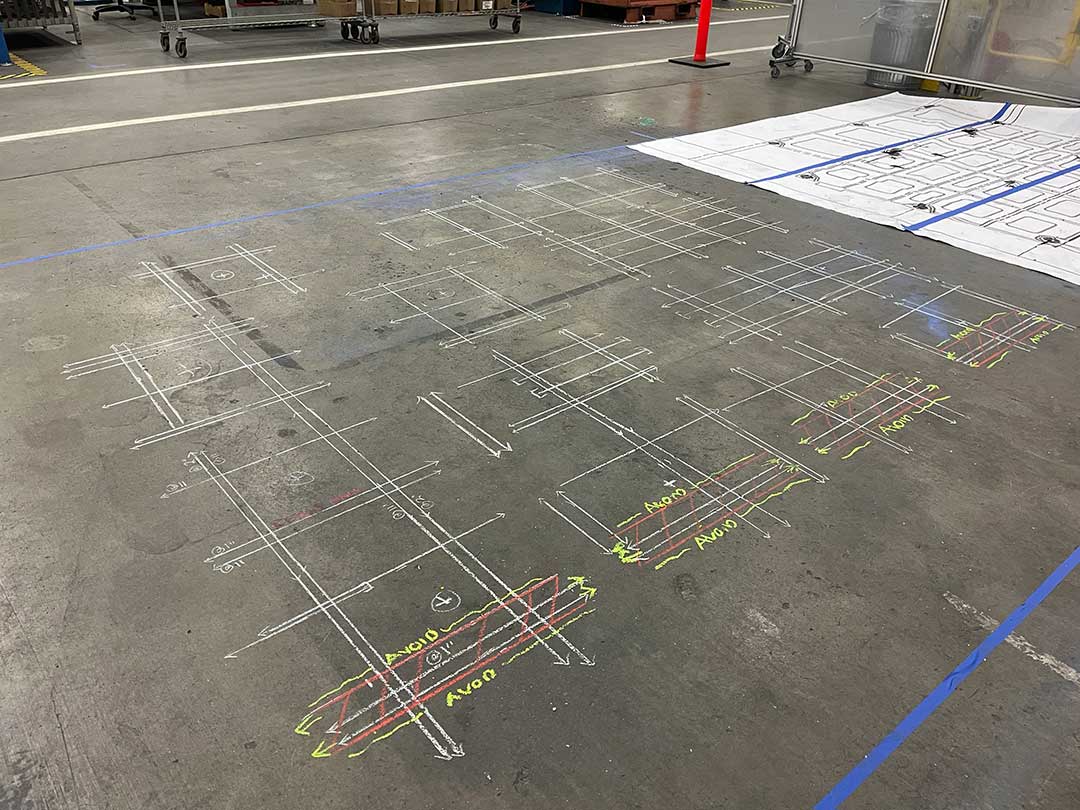

Before beginning core drilling, GPR concrete scanning is performed to inspect the structural state of the target area. This preliminary step aids in identifying any potential obstacles underneath the surface, ensuring the drilling process is safe and efficient. Core drilling involves mounting a cylindrical drill on a machine, which then rotates its shaft to penetrate the surface, extracting a cylindrical sample, or “slug.”

The extracted material is valuable for geotechnical analysis, offering insights into the structure’s composition and integrity. The resulting holes can be used to place different construction materials, making this technique essential in various settings, such as masonry surfaces and concrete structures.

Reasons to Implement Core Drilling Techniques

Core drilling has many applications, but its primary purpose is obtaining undisturbed material samples. These samples help analyze the quality, structural integrity, and strength of the materials, which is crucial for assessing their capacity to support weight and withstand environmental factors. This data is critical to ensuring that construction projects maintain the highest levels of safety and durability.

Moreover, core drilling is useful in creating passages for installing utilities, such as HVAC systems, electrical wiring, and plumbing pipes. Its precision ensures minimal disruption to existing structures, facilitating both renovations and new constructions.

Projects That Benefit from Core Drilling

Core drilling is indispensable across a range of construction projects. It is especially beneficial in creating subsurface structures like tunnels, pipelines, and parking garages, where precision and structural safety are paramount. The method is also crucial when installing wiring and conduits for electrical services in both residential and commercial buildings.

Specialized techniques such as horizontal directional drilling (HDD) are employed in complex projects, like those within the gas and oil sectors, where the aim is to install pipelines with minimal surface impact. This precise method ensures that existing pipes and structures remain intact.

In renovations, core drilling enables the efficient installation of essential systems, including HVAC installations and telephone lines. Its swift execution makes it a favorable choice for projects under tight deadlines.

Reach Out to RainierGPR for Core Drilling Expertise

We at RainierGPR pride ourselves on being leaders in construction solutions. Our comprehensive services are backed by advanced technology and a highly skilled team, ensuring effective solutions for any core drilling needs. Whether dealing with confined spaces or large-scale concrete testing projects, our dedication to safety and quality makes us the ideal partner for all your core drilling requirements.

For inquiries about our core drilling services, including concrete core drilling, GPR scanning, and other specialized methods, please contact us. Our commitment to excellence and innovation ensures we can tackle any challenge with precision and expertise.

Common Questions About Concrete Core Drilling

What is the Function of Drilling Cores into Concrete?

The main function of drilling cores into concrete is to carve out circular, precise holes within concrete structures. This method is crucial for creating passages for utilities, such as plumbing, electrical, or HVAC systems. Additionally, it is employed to collect samples for analysis and testing, ensuring that materials meet project specifications.

Typical Uses for Core Drilling in Building Projects

In construction, core drilling serves numerous purposes. It allows for the installation of plumbing and electrical conduits, facilitates the setting of anchoring bolts, and provides access points for communication lines. Core drilling also helps create access for maintenance in walls, floors, and ceilings.

How is the Concrete Core Drilling Method Conducted?

The core drilling method involves a specialized drill fitted with diamond-tipped bits. Initially, a ground-penetrating radar might be used to detect hidden obstacles. The machine then steadily advances through the concrete, forming a cylindrical hole without damaging the surrounding area.

Distinctions Between Core Drilling and Standard Drilling Methods

Core drilling differs from traditional drilling in that it creates clean and precise holes without impacting the integrity of the concrete. Standard drilling techniques may cause cracking or chipping, while core drilling uses a diamond-encrusted bit for smoother, more accurate cuts.

Equipment Utilized in the Core Drilling Process

Equipment used in core drilling includes drill rigs, which can be handheld or rig-mounted, and diamond drill bits. These tools are selected based on the size and depth of the hole required and the hardness of the material being drilled.