Concrete Scanning

Ground penetrating radar (GPR) can detect embedded or hidden objects within the near subsurface.

GPR Concrete Scanning

GPR Concrete Scanning: Essentials for Construction Site Safety

The unseen elements within concrete can pose significant challenges in both construction and renovation. At RainierGPR Concrete Scanning, we specialize in ground-penetrating radar (GPR) concrete scanning services to address these issues. Our advanced imaging technology excels at locating rebar, post-tension cables, and other potential obstructions within concrete structures.

We take pride in offering precise detection capabilities that play a crucial role in reducing risks and enhancing the efficiency of your projects. Our dedicated team is equipped to fulfill various concrete scanning needs. We are committed to delivering detailed and prompt service, ensuring that safety standards are maintained and project timelines are respected. Partner with us to gain insights into the complexities of your construction site, leading to informed decisions and smooth project execution.

Key Takeaways

Precise GPR Scanning:

Our cutting-edge GPR technology provides detailed scans, ensuring project safety and efficiency.

Advanced Imaging:

We can locate objects within concrete with high accuracy using our state-of-the-art equipment.

Efficient Execution:

Partnering with us guarantees that your construction and renovation projects are carried out safely and effectively.

Ground Penetrating Radar for Concrete Assessment

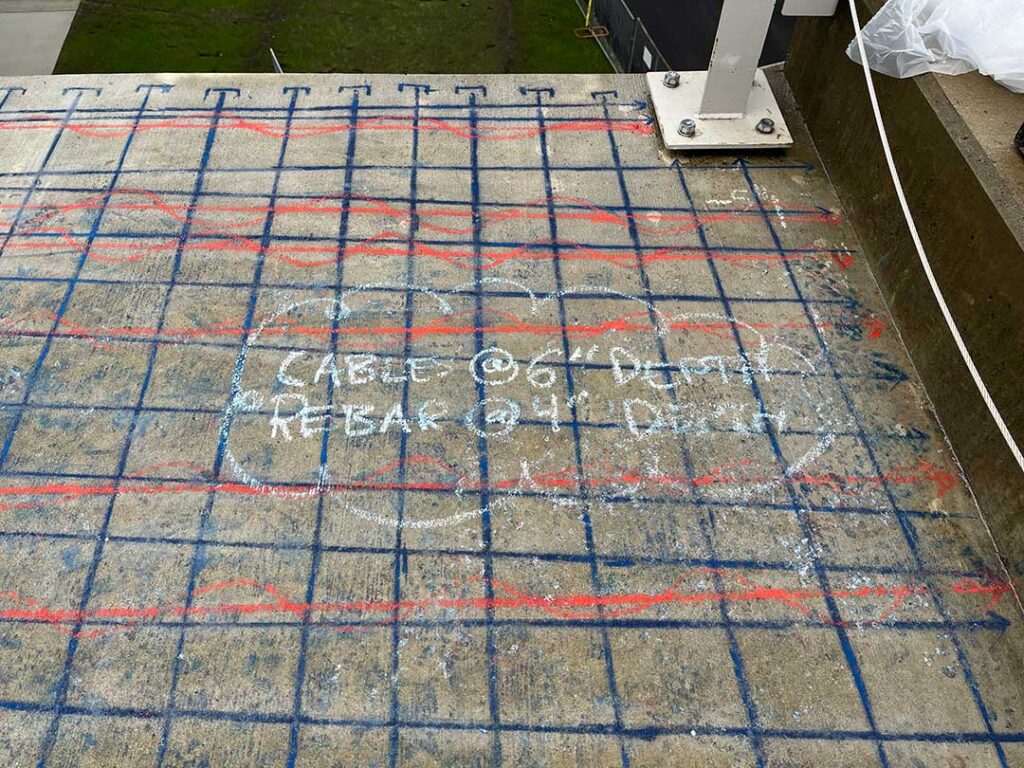

Using electromagnetic techniques, our team conducts thorough scanning and imaging of concrete structures. Ground Penetrating Radar (GPR) offers a non-intrusive method for evaluating the internal condition of concrete, brick, or asphalt without causing damage. This advanced technique is crucial for detecting hidden elements, such as rebar, post-tension cables, and voids, thereby enhancing safety and accuracy in both new construction and renovation projects.

Our commitment to precision ensures that each project benefits from a comprehensive assessment, significantly reducing the risk of structural failures and additional costs. This approach is particularly crucial for Slab On Grade (SOG), Pan Decking, and Structural Slabs, where knowing the exact location of embedded components is vital.

GPR Concrete Scanning Applications

Here is an overview of applications and how our services address each requirement:

| Applications | Services Provided |

|---|---|

| Integrity of Structural Elements | We identify inconsistencies such as cracks or internal disturbances to ensure the durability and strength of concrete structures. |

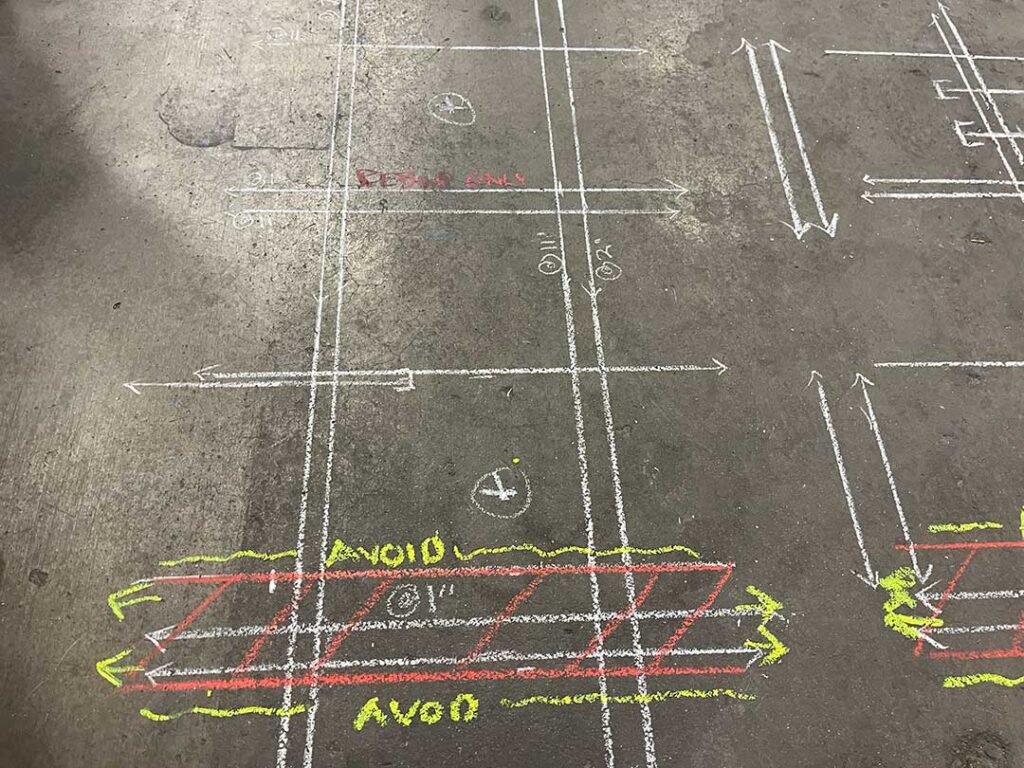

| Rebar Localization | Our GPR services precisely map the placement of rebar within concrete structures, catering to both new constructions and renovations. |

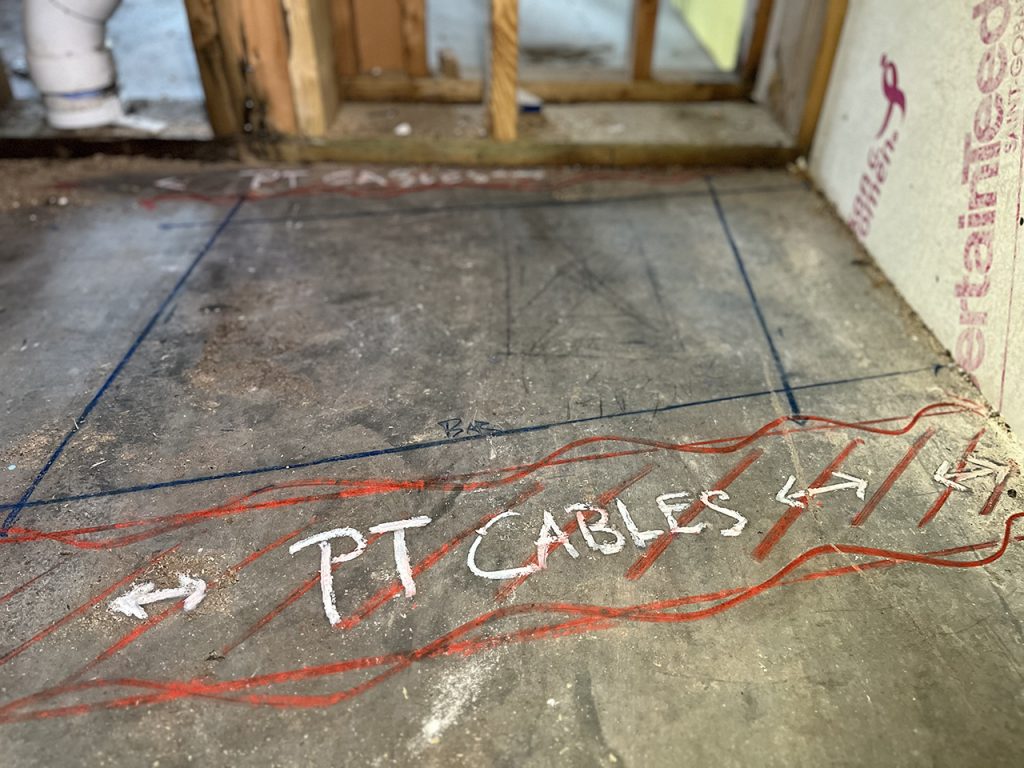

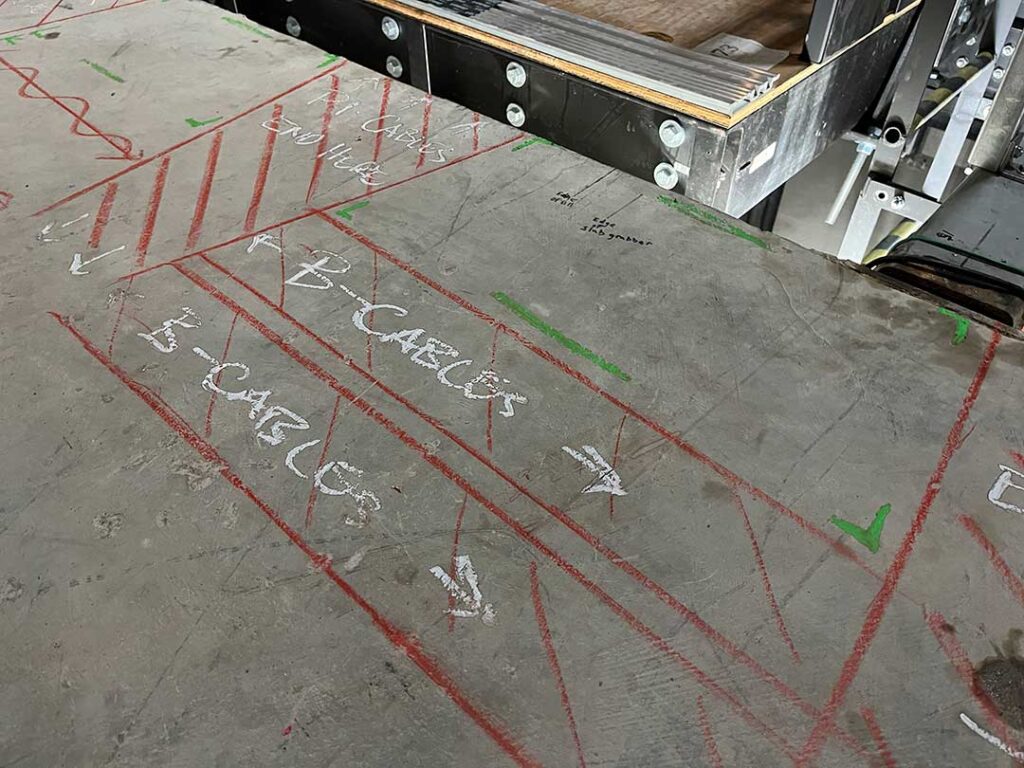

| Post-Tension Cable Mapping | Our GPR services accurately identify the layout and condition of post-tension cables, making them suitable for both new constructions and renovations. |

| Concrete Slab Thickness Gauging | We deliver accurate measurements of slab thickness to meet specific engineering standards. |

| Condition Evaluation of Bridge Decks | We assess the health of bridge decks by detecting delamination and identifying potential failure areas. |

| Identification of Voids | Our radar identifies cavities within the concrete that could compromise structural integrity. |

| Tunnel System Assessments | We perform thorough inspections to ensure the stability and safety of tunnel structures. |

| Cover Depth on Reinforcement Estimation | We determine the depth of concrete over reinforcement bars to prevent corrosion and ensure long-term durability. |

Applications of Ground Penetrating Radar (GPR) in Concrete Scanning

Our GPR technology is invaluable for examining concrete structures like Slab On Grade (SOG), Pan Decking, and Structural Slabs. Knowing the exact location of embedded components is crucial for their safety and longevity. Each project benefits from our commitment to precision, which significantly minimizes the risk of structural issues and additional expenses.

Scanning Post-Tensioned Cable Decks

We utilize ground penetrating radar (GPR) to locate post-tension cables in a slab on grade accurately. This process is essential for maintaining structural safety and integrity during construction or renovation. Precisely identifying these components before making any modifications is crucial to prevent damage.

Inspecting Reinforced Lightweight Concrete Decks

Our GPR services are perfect for scanning pan decking structures, which play a crucial role in modern construction. Our technology enables us to verify the presence and condition of reinforcing steel and assess the consistency of the concrete.

Evaluating Structural Slabs’ Integrity

In the analysis of structural slabs, ground penetrating radar (GPR) is a vital tool for detecting changes, voids, and potential defects. Accurate scanning helps maintain the structure’s integrity, ensuring proper maintenance and adequate safety measures.

Analysis of Beams and Columns

We utilize GPR technology to evaluate the condition of beams and columns. By identifying reinforcement patterns and potential issues within these crucial structural elements, we help ensure their stability and load-bearing capacities.

Locating Reinforcement Bars

Detecting rebar within concrete is a primary application of GPR. We perform precise mapping of steel reinforcement locations, facilitating construction activities that involve drilling or cutting through concrete.

Surveying Block Wall Constructions

For concrete masonry unit (CMU) walls, we employ GPR to assess and verify the filling status of the block walls. This ensures they meet design specifications and improves our understanding of their structural conditions.

Scanning Preformed Composite Decks and Walls

Our GPR expertise includes examining precast decks and walls. This is crucial for verifying the placement and density of structural elements, aiding both the fabrication process and subsequent installations.

Inspecting Waffle Slab Construction

Waffle decks necessitate our precise GPR scanning to verify the correct installation of the intricate rebar network and assess the slab’s condition, which is crucial for ensuring the structure’s overall stability.

Checking Hollow Core Slab Composition

For hollow core decks, we use GPR technology to analyze internal features, including detecting voids, to ensure these precast structures maintain their intended structural performance over time.

Enhanced Subsurface Imaging Using Electromagnetic Detection

We utilize the exceptional capability of GPR to detect subsurface objects within concrete. By sending electromagnetic energy into concrete structures, GPR captures reflected signals from materials like rebar, conduits, and voids. These reflections create detailed images of hidden features, helping us understand what lies beneath the surface without causing damage.

- Safety in Construction: GPR outlines the location and depth of embedded objects, preventing potential construction mishaps.

- Efficiency and Precision: The technology provides fast and accurate real-time assessments, keeping projects on schedule.

- Non-Destructive: Unlike other methods, GPR preserves the concrete’s integrity during scanning.

- Expertise: Our detailed subsurface imaging is essential for both small and large construction projects.

Our GPR services outperform traditional X-ray techniques by being non-destructive and offering immediate results. Whether pinpointing rebar, uncovering post-tension cables, or mapping out voids, GPR is an invaluable asset for any task requiring accurate concrete assessment.

Our specialists provide meticulous scans with detailed analyses. We are committed to thoroughly exploring the subsurface of concrete and offering actionable insights. GPR’s convenience and efficiency over X-ray are clear—there’s no radiation risk, and the data acquisition is faster, avoiding project delays.

Applications for GPR

Versatility across Different Materials

Overview of Scanning Methods

Our ground-penetrating radar (GPR) technology provides advanced subsurface mapping not only for concrete but also for diverse materials like brick and asphalt. Its adaptability allows us to deliver precise results in various construction scenarios:

Our tools enable us to approach each project with confidence, enhancing efficiency and ensuring that every decision is informed by accurate subsurface data.

Opting for our services ensures a comprehensive and expert approach to subsurface imaging. We are dedicated to upholding the integrity and safety of all construction projects.

By incorporating ground-penetrating radar (GPR), we can now examine concrete depths of up to 18 to 24 inches, showcasing the value of our advanced diagnostics. Our services consistently strike a balance between thoroughness and minimal disruptions.

We cater to a wide range of construction needs, enabling ongoing work to proceed uninterrupted. Our scanning ensures that every decision you make is based on accurate and comprehensive data.

Rely on our team for precise GPR concrete scanning and imaging services. Quality, professionalism, and cutting-edge technology form the foundation of our work, providing your projects with the clarity needed to achieve superior outcomes.

Summary of Concrete Scanning Role

Concrete scanning plays a critical role in construction and structural renovation. Our noninvasive technology assures structural safety, optimizes workflow, and upholds industry standards.

- Accuracy: We detect embedded objects like rebar, conduits, and tension cables with precision, ensuring accurate project planning.

- Safety: Our methods reduce the likelihood of damage and injury, prioritizing the well-being of everyone involved.

- Efficiency: By minimizing potential errors and delays, our processes save time and reduce costs.

- Compliance: Meticulous mapping supports adherence to legal and regulatory standards, ensuring project compliance.

By integrating advanced diagnostic capabilities, we can scan concrete depths of up to 18 to 24 inches, providing valuable insights while minimizing disruptions. Our services cater to various construction needs, allowing ongoing work to proceed smoothly.

Trust our team for precise concrete scanning and imaging services. Our foundation of quality, professionalism, and cutting-edge technology equips your projects with the clarity needed for superior outcomes.